A paper folding machine can be a value-add for any digital printer, print shop, mail house, e-commerce center or other commercial/office setting.

The benefits and capabilities of paper folders today go beyond the fold. Folding solutions can lead to slitting, batching, perforating, scoring, gluing and other finishing options. The right machine brings with it increased production efficiency, improved quality, expanded job opportunities and decreased overall costs.

As a bindery and finishing solution and equipment provider, we have solved post-press inefficiencies within many industries. The key to purchasing the right folding machine starts with knowing what capabilities will bring your company the most value, what questions to ask and how to calculate a return on investment.

CLICK THE LINK TO GO DIRECTLY TO A SPECIFIC STEP:

Save the entire guide. Download it today!

Get a pdf of this entire guide to save and share with your team. Know what checks to make and questions to ask when buying an automatic paper folding machine for commercial or industrial use. Gain professional insight on what options to expect in paper folding machines today. Know how to evaluate the Return on Investment when buying or upgrading a paper folder. See the most popular folds in the industry right now.

Get a pdf of this entire guide to save and share with your team. Know what checks to make and questions to ask when buying an automatic paper folding machine for commercial or industrial use. Gain professional insight on what options to expect in paper folding machines today. Know how to evaluate the Return on Investment when buying or upgrading a paper folder. See the most popular folds in the industry right now.

Where should we send it?

What should I expect from a commercial paper folding machine today?

- Ease of use and highly compatible with multiple finishing options

- Increased productivity that removes inefficient and duplicate efforts

- A reduction in costs through labor, fewer shutdowns and repairs

- Improved output with less waste, more sheets per hour and higher quality

- Increased profit opportunity through expanded job capabilities

- Efficient, operator-friendly controls and set up

8 Checks Before Purchasing a Paper Folding Machine

Knowledge is power, no matter whether you’re a digital or offset press, novice or experienced production operator. Make these checks before purchasing or upgrading your paper folding equipment to prevent your company from a jam.

1. Ease of Operation Evaluation

Evaluate the manual setup and equipment downtime between changeovers and training new hires.

- Does your current equipment have HMI touchscreen tutorials on machine setup?

- Can your team store multiple jobs on the touchscreen to reference previously run jobs?

- Does the equipment include setup guides for maintenance procedures?

- Do the fold plates have micro adjustments?

- Does the machine have a batch counter?

- Are there limitations in jobs due to your finishing capabilities?

Your operators are your most valuable resource. Updated technology and equipment allows them to do their jobs efficiently and with less frustrations. If equipment is outdated or difficult to set up between jobs, work place production will drop and turnover is likely.

2. Efficiency & Capability Evaluation

Start with your current operations. Evaluate where inefficiencies exist in your post-press equipment and processes:

Evaluate the manual setup and equipment downtime between changeovers and training new hires.

- Are there consistent delays or bottlenecks?

- Are there duplicate efforts or wastes due to how jobs are laid out?

- Are there labor concerns, both costs and physical fatigue?

- Are there limitations in jobs due to your finishing capabilities?

The most valuable finishing solution for your company may involve scoring, slitting, perforating and stacking, all viable options in today’s finishing and bindery equipment. The best solution starts by determining your goals and then finding the applications that helps you achieve those goals.

Paper Tip: Static electricity can build up on paper during printing, causing paper jams and double feeds in folding. Resolve by laying paper on a metal surface to discharge static electricity, or add a static eliminating kit to your folder.

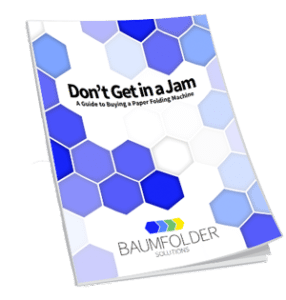

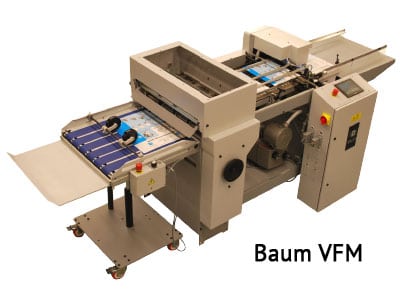

For example, the BAUM VFM slitting machine takes 11X14 printed 2 up work and then slits sheet to be folded 2 up 8.5 x 11 letter Z fold. This slitting operation doubles production and cuts time and costs.

See the BAUM VFM in action:

3. Productivity

Determine what productivity you want to achieve. The productivity of a folding machine involves a combination of its speed, feed tray/table capacity and delivery exit conveyor. For example, if you need longer uninterrupted production, a larger pile or continuous feeder is just as important as the machine’s speed.

Machine speed, often rates as inches per minute, is based on the maximum speed at which the folding machine will run paper through. This calculation is based on the paper folding machine industry standard of 70 gsm paper folded into a letter fold (C fold). This does not take into account time to reload the paper feeder.

4. Volume

The most common obstacles customers face are caused by purchasing paper folding machines that are too small for their requirements. Choose a paper folding machine that is suitable for the amount of work you are doing today and plan to do in the future.

To determine accurate volume needs, look at your company’s:

- Yearly average run sheet size

- Job layouts and related inefficiencies or waste

- Current needs and standard jobs

- Expanded capabilities you would like to offer

- Future growth opportunity and industry trends

“We are a quickly growing print shop with several locations and more on the horizon, and plan to purchase any other needed parts from you in the future. Thank you again for the wonderful services!”

– Dan Polden, DigiCopy

For example, the BAUM 20 Continuous feed can produce 8200 inches per minute, and when the BAUM two-tier stacker is added, you can gain additional output.

See the BAUM 20 Continuous feed in action:

5. Paper Thickness & Coating

Select a machine that is capable of handling the weights and types of paper you use. Consider which coating options are trending in your industry, such as matted, glossy, soft finishes or foiled.

The recommended paper weight for a paper folding machine is often quoted based on non-coated paper. There is typically a 30gsm difference for a light coating and 50gsm for heavy coating. At Baumfolder, we encourage customers to let us do a test run before purchasing.

Ask the supplier about the number of feed tires. The more (and wider) the feeder tires that initially pull the paper into the machine, the better. This helps the initial pick-up of the paper, coated or non-coated, as well as stopping the paper from twisting and causing a variety of problems.

Quality Tip: Hand fluff the paper before loading in the feeder.

Watch the BAUM 1620 IPF into CF20 4 panel Z fold heavy stock:

6. Paper Fold & Size

Most manufacturers upon request will run samples of special paper size and folds. At Baumfolder, we encourage sample runs before purchase to verify the equipment will run your job. If not, we can provide a solution that is tailor made with some of our selected partners to provide a custom solution. Our support team can provide help before and after the purchase of equipment.

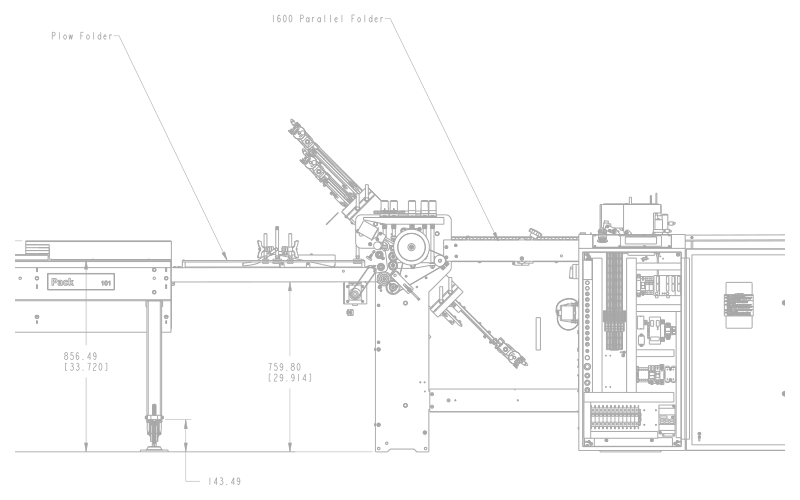

Check out how the Century Series Solution with Feeder, Folder and Wrapper and Card Inserter increases efficiency and options in packaging.

This application starts out with an 8.5 x 11-inch piece of paper or personalized document. The paper (packing list, invoice, etc.) is folded twice and fed upon a conveyor. Also, an additional card inserter can be added for promotional information. Package efficiently while adding advertising inserts on or in shipping cartons.

Efficiency Tip: At the end of the day, don’t leave your feeder loaded. Always keep your stock in a controlled environment when possible for the best feeding and folding.

7. Feed Tray Capacity & Capabilities

Capacity of the folder’s feed tray, which is the number of sheets that can be loaded into feed tray, is very important in picking a folder that meets your needs. The exit end of the folder is just as important. Does the sheet need to go into another operation? Can the manufacturer provide a special conveyor that will stack, insert, batch or convey material to next operation?

8. Maintenance & Warranty

It is always a plus when there are extended warranties and/or technical and maintenance support. Find a supplier with an on-site technical support and maintenance team. Ask if parts are readily available.

At Baumfolder, we have a fully staffed technical support, parts, shipping and product management team who have received multiple achievements on customer satisfaction. We can proudly say our customers know they can count on the Baumfolder service team when they need us most.

Folding Tip: Heat can cause paper to distort and curl. Cool paper on a flat surface before loading into a paper folding machine to avoid problems.

Determining ROI when Purchasing a Paper Folder

In a world where print jobs are becoming more and more specialized and the internet is a growing competitor, companies can’t afford to take a “wait and see” approach on expanded capabilities and production efficiency. When calculating ROI to determine the value a paper folding solution can bring your company, take into consideration:

- The costs of steps or processes that can be eliminated.

- Costs savings due to a reduction in labor and less waste.

- Additional print jobs out the door per day due to faster production.

- Expanded job capabilities and increased profit opportunity.

- Increased efficiency during set-up, operations and job changes.

- The value of a knowledgeable manufacturer that stands behind every machine with technical support and service.

Building Precision Solutions

Expand your capabilities with the latest in bindery and finishing equipment from Baumfolder Corporation in Sidney, Ohio. We have hands-on knowledge in digital printing, mail logistics, e-commerce, automotive, retail and food industries and more.

In today’s competitive, global environment, let us be your solution to capturing value and improving efficiency.